Designed to secure and protect banknotes together for easier management and sorting, cash strapping machines use heat binding to connect pieces of tape together and bundle a number of banknotes. And when used in conjunction with pre-printed tape, it helps users identify and safely move the banknotes.

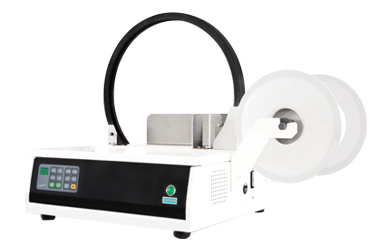

Julong offers a range of reliable and efficient cash strapping and binding machines that utilize our patented instant heat technology and eco-friendly POE binding material. Easy to use and with fully-customizable features, our machines handle up to 1000 banknotes per bind, and are supported with responsive technical support. Contact us today to get a free quote.

Our well-crafted machines are suitable for handling cash of any capacity.

JL109 double-cross 1000 banknotes into one bundle simultaneously within 20 seconds. In addition, it applies not only three straps (one along and two across), but also bonds the three straps together.

With its outstanding capability, JL112 Fully Automatic Banknote Strapping Machine brings more benefits to your business process.

Featured with patented instant heating technology, high efficiency and environmental protection.Currency value adjusting mechanism meets various volume of banknote binding requirement.Vertical banknote binding with high speed and lower noise.

JL116 enables to print bundle information on tapes, which reduce risks caused by manual operation. Any changes for bundle information is easy without any cost.

We combine production ingenuity and customer experience for reliable cash strapping machines.

Equipped with our patented instant heat technology ensures secure strapping without any wait times.

User-friendly interface and LED displays increase productivity and reducing unnecessary adjustments.

Adjustable operation modes + modifiable tape arch makes processing bank notes so easy.

Manufactured using recyclable POE, the packaging films used on our machines are eco-friendly

Binding pressure is automatically calibrated within the system, ensuring the right fit in every use.

Strapping machine consumes less than 25 watts on standby, while active mode uses up to 300 watts.

Manufacturing of our cash strapping equipment is done within our world-class facility, handled by some of the best R&D and design specialists in the industry. Developing and building our machines in-house guarantees that our high production standards are consistently met and that our clients get the best machines.

Julong understands the need for quick and reliable technical assistance. In addition to fast remote technical support, we have various overseas sites in Germany, South Africa, India, and Saudi Arabia, on-site support for training, consulting, and repair is available as soon as needed.